|

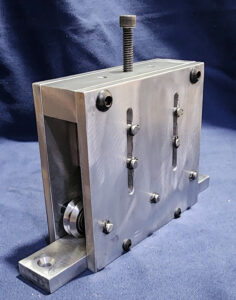

The wire straightener came from a need to remove the bend from coiled 9ga steel wire normally used with chain link fencing prior to the wire being cut to size and rolled to specific radius while making ribs for the spheres of the snowman project. |

|

|

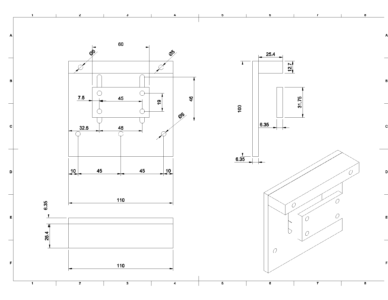

| general plans | parts for inner sliding carriage for upper rollers |

|

|

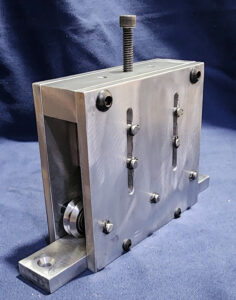

| one of two matched side plates | Bottom plate extends beyond frame to allow for clamping or has holes to allow screwing to a work surface or bench |

|

|

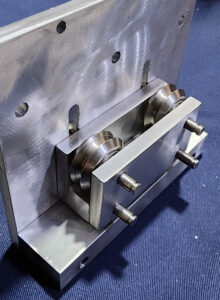

| Guide pins for the rollers and inner carriage. These are 5mm rods with snap ring groves. | v-grove rollers |

|

|

| Assembly of first side plate to top plate used 1/4-20 screws. Then inner carriage is assembled using 5mm rods extending through side plate slots. | Inner carriage completed with v-grove rollers |

|

|

| Adding the fixed rollers. Note roller spacers not shown in this image but are needed to keep fixed roller is the same vertical plane as the roller in the inner assembly. If the fixed rollers are allowed to slide then the wire will not straighten horizontally and vertically at the same time. | Adding the second side plate on with additional 1/4-20 screws and snap rings. |

|

|

| End view of tool finally turned right side up. Note cap head bolt added to top plate that forces down the inner carriage to apply pressure to the wire to be straightened |