The Fan came about one September morning while I was sitting at my desk and everyone who walked by banked an empty can, bottle, or other garbage off my wall and into my trash can. I decided that it would be fun if the can jumped out into the hall way when someone through stuff at it. Perhaps even better moved, would if the can through the stuff back out into the hallway. A few days later I was wondering around on the web and happened across Larry Lunds site. It is here that I found “Trash Can Trauma”, A Carl Chetta creation. This idea of a creature popping out of the trash can as people walked by in the hallway was a winner, I would just have to scale down “Trash Can Trauma” from a 45 gal. trash can to something more appropriate for an office. However, as I checked out the rest of Larry’s site I came to find that Carl had already created a little brother to “Trash Can Trauma” called “The Can”. Their were two things that I did not like about “The Can”, first was that only a head came out and second that the can only grew to a little over 3 1/2 feet tall. Despite these two drawbacks I had to create my own version to be placed in the office.

Because Lary and Carl already have a good How-To for the construction of both on Larry’s site, I will only display the modifications made to the original, in order to achieve a can that has a head and body come out the top while feet and legs shoot out the bottom to become a 5 foot 8 inch tall creature.

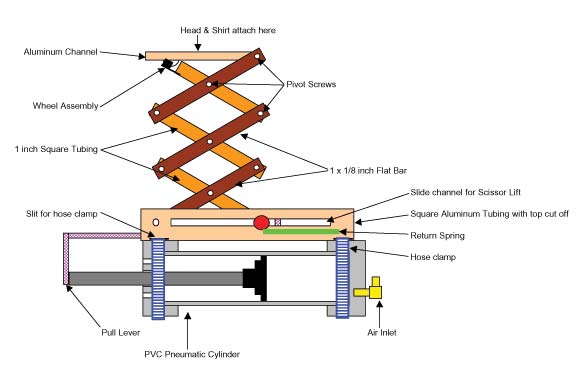

The scissors mechanism is made up of five cross of 1 inch square x 6 inch long aluminum tub and two 1 x 1/8 x 6 inch flat aluminum bars. Holes for #10 screws are drilled in the center and 1/2 inch from the end of each piece. With the exception of the top tub, which is cut short to accommodate a wheel. The wheel allows the aluminum channel to smoothly pass.

View of partially extended scissor

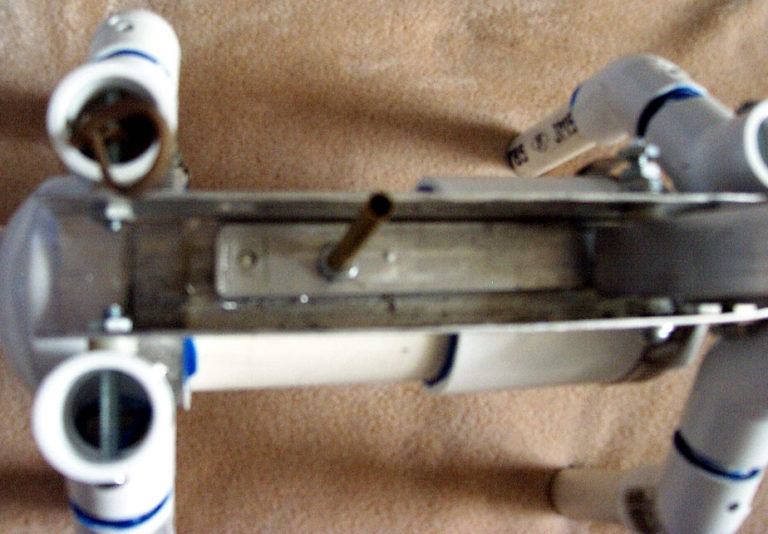

The scissor rides in a track made from a piece of 1 1/2 inch square aluminum tubing with one side cut off (channel of the correct size was not available, so I made my own). The bar and pin seen in the bottom of the track is to pull the scissor legs together.

Top View of Track

Side View of Track

Front View of Scissor

In the side view please note the hose clamps that attached the track to the PVC air ram, along with the mounting of the legs. The four legs fit into corresponding 1/2 inch PVC end caps that were first screwed to the wood from in the bottom of the can.

Top of scissor mechanism

The wheel was added to reduce friction of the small aluminum channel rubbing against the 1 inch tubing of the scissor. The wheel is a screen door replacement part. It was screwed to the tubing and rides in the groove of the small channel. One end of the channel is attached to the scissor mechanism with a screw which runs between the top of the top two bars of the scissor mechanism.

Inside view of can before and after scissor mechanism installed (click to view larger image)

Two vertical PVC air rams (2 inch bore 16 inch stroke) make up the legs. The shafts of the rams were made from 3/4 inch schedule 80 PVC pipe, and are the only support for the can when it is lifted off the ground. Special care should be taken to insure that the rams are perfectly vertical or they will bind against each other. This is do to their shafts being solidly affixed to a 3/4 plywood bass with two floor flanges. I feel that this is a good time to note that the plywood base that I used is not heavy enough to prevent The Fan from occasionally tipping over backwards when activated (when activated even the plywood jumps off the ground about 3 inches).

Trash can with hockey fan fully extended

The legs should be covers with some old pant legs or some cloth. Extending from the pant legs and attached to the base are a pair of cheep rubber feet filled with a little foam rubber.